The world of homebrewing has come a long way. While traditional methods involved meticulous gathering and processing of various ingredients, the advent of beer kits has democratized the art of brewing. Much like a ready-made cake mix simplifies baking, a beer kit streamlines brewing by offering pre-measured, prepared ingredients. However, akin to a gourmet cake requiring more than just a mix, crafting an exquisite beer involves more than following the steps on a beer kit.

This guide aims to explore techniques and strategies that can transform your regular homebrew into a work of art.

Beyond the Basics: Understanding Beer Enhancers

Understanding the biochemistry of brewing can greatly benefit your beer. Yeast converts sugars into alcohol and carbon dioxide through fermentation. This process prefers simple sugars like glucose or fructose. A beer enhancer essentially adds these simpler forms of sugars—in this case, malt extract and dextrose—making the yeast's job easier and more efficient.

Employing a beer enhancer adds depth to your beer’s flavor profile and facilitates a cleaner fermentation process. The dextrose ensures that there's no residual sweetness in the brew, thus allowing the more subtle notes of malt and hops to shine through. This approach provides the added benefit of higher alcohol content without negatively impacting the beer’s taste.

Crafting Flavor Profiles: The Extra Hop Dimension

Choosing Your Hops

The hop plant contributes the bitter and aromatic characteristics to beer. The choice of hops can depend on the type of beer you're aiming to brew. For instance, lagers pair exceptionally well with hops like Green Bullet or Cascade. Green Bullet offers a traditional bittering quality, while Cascade adds citrusy, floral notes.

Timing and Technique

The timing of adding these complementary hops is also crucial. Whether you choose to do it during the boil or later during fermentation (a technique known as dry hopping) can substantially change the aromatic and flavor profile of the beer.

The Wisdom in Waiting: Extended Fermentation

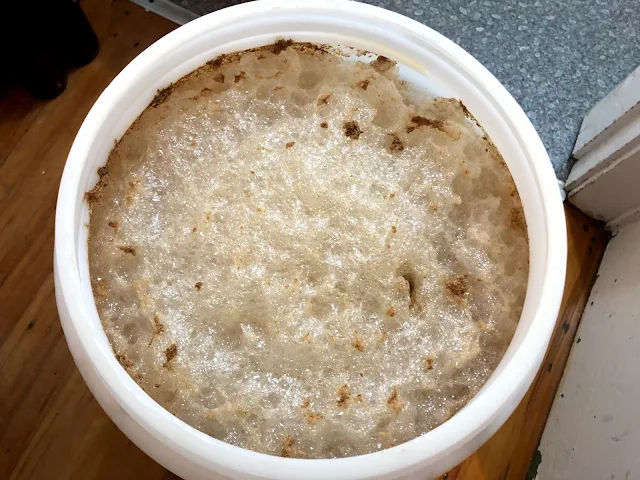

The Microbial Ecosystem

Yeast doesn't just work alone. A variety of microbes come into play, each contributing to the complexity of your brew. Over time, these flavors meld together, creating a harmonious blend that significantly improves the overall tasting experience.

Fermentation Vessels

The type of vessel used for fermentation can also influence the flavor. Whether it's a glass carboy, a stainless steel drum, or a wooden barrel, each adds its own set of characteristics to the brew. Thus, longer fermentation should not be seen just as a test of patience but as an artistic decision.

Navigating the Bottleneck: The Subtleties of Bottling

The Enemy: Oxygen

Exposure to oxygen post-fermentation can lead to a stale, cardboard-like flavor in the beer, a phenomenon known as oxidation. Minimizing this exposure is crucial during the bottling stage.

The use of a bottling wand, for instance, ensures that beer flows smoothly from the fermenter to the bottle with minimal agitation. This avoids unnecessary oxygen incorporation, preserving the integrity of your beer.

Temperature: A Crucial Variable

Temperature is not just a setting; it’s an active ingredient. During the initial two-day warm storage, the yeast is more active, aiding in secondary fermentation which helps in natural carbonation. Later, moving the bottles to a cooler, dark setting stabilizes the beer and allows the yeast to slowly refine the brew's flavors.

The Balanced Brew: Advantages of Batch Priming

Batch priming serves multiple purposes. Firstly, it guarantees a uniform level of carbonation across all bottles. Secondly, it mitigates the risk of over-carbonation, a dangerous situation that could lead to exploding bottles and wasted beer.

When batch priming with sugar, it's also easier to calculate the precise amount of sugar needed to achieve the desired pressure within the bottle, reducing guesswork and increasing consistency.

The Balancing Act of Alcohol Content

The Sugar-Yeast Equilibrium

Yeast metabolism is sensitive to sugar concentration. Adding too much sugar can stress the yeast cells, leading to incomplete fermentation or even yeast death. Thus, striking the right balance is critical.

Nutritional Supplements for Yeast

To aid the yeast in metabolizing extra sugar, brewers often turn to yeast nutrients. These contain essential minerals and vitamins that help the yeast thrive, even in sugar-rich environments.

Clarity Through Fining Agents and Cold Crashing

Types of Fining Agents

Fining agents like isinglass, gelatin, or Irish moss work in unique ways but achieve the same result: a clearer beer. The choice of fining agent can also subtly influence the beer’s final flavor.

The Cold Crash Method

Cold crashing is the process of rapidly lowering the beer's temperature just before bottling. This causes the particles and haze to precipitate, resulting in a clearer brew.

Upgrading Your Arsenal: When to Scale Up

Need for a Bigger Kettle

As you become more comfortable and experimental with your brewing, a bigger kettle allows for more brewing flexibility. It gives you the freedom to create larger batches or more complex brews involving multiple ingredients.

Future-Proofing Your Setup

Moreover, investing in quality equipment from the outset can save both time and money in the long run. After all, a larger kettle is not just an accessory; it’s an investment in your brewing future.

The art of brewing is an ever-evolving journey, replete with opportunities for experimentation and mastery. So, as you fill that glass with your next homebrew, remember, each drop contains not just malt and hops, but the essence of a craft honed through time and dedication. Cheers!

Embracing the Complexity of Craft Brewing

Having navigated the complexities of homebrewing, from understanding the biochemical nuances to fine-tuning the fermentation process, it becomes apparent that brewing is both an art and a science. This intricate balance allows for limitless possibilities—each decision you make, from the type of malt to the timing of hop addition, culminates in a beer that is distinctly your own. But the process doesn’t end with the last sip; each brew serves as an enlightening experience, offering insights that can be integrated into future brewing endeavors.

The Community Aspect: Shared Experience and Knowledge

Homebrewing is not a solitary venture. There's a robust community of like-minded individuals, each brimming with their own techniques and secrets. Sharing your own experiences and learning from others can deepen your understanding of this craft. Platforms like forums, local brew clubs, or even social media offer a wealth of collective knowledge. In these spaces, you can discuss the intricacies of yeast strains, debate over the ideal fermentation time, or simply share your success and, yes, even your failures.

The Journey Over the Destination

In the world of craft brewing, the journey truly is more fulfilling than the destination. The process, from that initial spark of inspiration to the final, frothy pour, is where the joy of homebrewing lies. It's not about fast results or shortcuts but the gradual, learned art of making something extraordinary out of ordinary ingredients. So, the next time you find yourself impatiently waiting for that batch to ferment or agonizing over the perfect hop blend, remember: you're not just brewing beer; you're crafting an experience, both for yourself and those lucky enough to share in your brew.

Whether you're new to homebrewing or have been at it for years, it's important to recognize that each batch presents its own set of challenges and opportunities. Thus, the act of brewing is a perpetual lesson, continually refined but never truly mastered. Cheers to that eternal quest for the perfect brew!